Bespoke Structural Glazing

Here at Glass Interiors, we proudly offer a range of bespoke glazing designs to our customers, ensuring that we meet your structural glazing requirements every single time. Our well-trained experts have the necessary structural engineering skills to provide high-quality and efficient services when it comes to incorporating structural glass into your building. Why settle for anything less than the best for something so important?

With a wealth of experience in everything from glass floors to curtain walling, we’re more than capable of designing structural glazing systems that are suitable for both interior and exterior use. Should you intend to use glass as a focal point of your building’s design, Glass Interiors can produce the perfect solution, no matter what your project may be. Simply get in touch, and we’ll see what our structural glazing team can do for you.

Whether you want single-glazed or double-glazed structural glass, box and plate configurations or frameless with steel spider fittings, fire-rated glass for escape routes, or powder-coated framework in any RAL colour – we can do all of this, and so much more, at Glass Interiors.

Read-More...

Bespoke structural glass systems in the UK

There are many ways to implement structural glazing, with exterior curtain walling and shopfronts being some of the most popular. Durable yet transparent structural glass maintains the security of your building while creating a beautiful aesthetic and increasing the amount of natural light.

Or how about walk-on glass floors, constructed from 33mm thick toughened glass supported by a framework of stainless steel? Widely used in commercial and residential buildings alike, a glass floor provides a creative interior design option while also being extremely strong and completely safe.

For the ultimate elegant entranceway, your building could even have a glass atrium, with a wonderfully open structural glass roof and facades. If you like the aesthetic of glass but drastic alterations aren’t viable, glass barriers are a great alternative. With many years of industry knowledge behind us, our team of glazing experts can help you to successfully design and install your ideal structural glazing system.

Contact us today for custom structural glazing

Using a combination of only the best toughened glass and an aluminium glazing shoe, Glass Interiors achieves the smoothest finish on every structural glazing installation we carry out. We work as closely as possible with dedicated project management teams to arrive at the perfect design, which meets all architectural design and building safety requirements. The stunning final result is sure to exceed your expectations.

When you choose Glass Interiors for your bespoke structural glazing system, we guarantee that you’ll receive a fantastic addition to your building that will last for many years to come. Whether you’re searching for shop front glass or something more intricate on a much grander scale, get in touch with our team and we’ll gladly discuss your structural glazing ideas. With our hard-earned expertise, we can guide your practical and aesthetic choices.

You can contact Glass Interiors via telephone on 0203 793 5455 or by e-mail at info@glass-interiors.co.uk, or by filling out our online form. We’ll get back to you as soon as possible to speak with you about your requirements, and help you to determine the best structural glass option for you.

View our Structural Gazing FAQs at the end of this page to learn more about structural glass.

See-less

Curtain Walling & Shopfronts

Overview

Curtain walling systems provide the perfect solution for the external cladding of any building capable of allowing in large amounts of natural light through large expanses of clear glass.

This creates a feeling of space and provides the perfect interface with the outside world, all while maintaining the safety, security, and comfort levels of the building’s internal environment for the benefit of its occupants.

Our aluminium system offers both single and double-glazed options and is based around a box and plate configuration while creating a thermal barrier. Our frameless glazed system uses structural spider fixings to create seamless configurations.

Walk-on Glass Floors

Overview

We provide walk-on glass floors for residential and commercial application. 1.2 U-Value can be achieved using our offset double glazed system. The 33mm thick glass is supported by a stainless steel framework with glass support beam.

We work closely with architects and contractors to design our systems to suit each individual project. We can also provide structural calculations and drawings to satisfy building control requirements.

Framework is powder-coated to any RAL colour and perimeter profile is kept to a minimum to maximise visibility of the glazing.

Atrium Glazing & Glass Barriers

Overview

We design & install glass barriers and atrium glazing up to 3kN line load, using a combination of toughened laminated glazing panels and our aluminium glazing shoe.

We supply full structural calculations for each project. The atrium glazing can also be fire rated up to Ei60 to compartmentalise office space and escape routes.

Please contact our design team for more information.

Structural Glazing FAQs

What is structural glass?

The term ‘structural glass’ refers to any type of load-bearing glazing. In place of a traditional wall, made of materials such as bricks, large panels of thick toughened glass are installed. There are lots of ways to integrate structural glazing into building design, including walls, doors, roofs, and floors.

The glass is an integral structural element, bearing weight horizontally and vertically with minimal additional support. Glass beams or fins, steel struts, spider fixings, and silicone sealants can be used to secure the glass panels without being too visible. This creates a practically frameless appearance.

The location, environment, and intended purpose of the structural glass will determine the size, shape, thickness, and bonding mechanism. This has to be carefully calculated, because structural glazing must withstand a variety of stresses, from wind and temperature changes to physical loads.

How does structural glazing work?

This type of architectural glazing is specially designed to be capable of supporting significant weights and transferring them to the building’s core load-bearing structure. Being more rigid than other traditional construction materials, structural glass can resist deformation well.

Loads can be distributed evenly through different techniques. Bonding structural glass panels to the building’s structure using a specifically formulated, high-performance silicone adhesive and sealant can achieve a seamless appearance, which is popular for modern commercial buildings.

Point fixing systems can discreetly attach panels to the building with minimal framing using small metal clamps. With bolted fittings, metal bolts are inserted into drilled holes in the panels to hold the glass in place elegantly. Metal framing can also be used if that aesthetic is preferred.

Structural glass designs are always meticulously checked to make sure that the correct calculations are used to determine the most suitable type of glass, installation style, and fitting materials. This is especially important in environments with potential exposure to severe weather conditions.

Where can structural glass be used?

In addition to its strength and rigidity making it suitable for use in load-bearing structural elements, many buildings use structural glazing for its transparency, as it’s put to best use in areas where unobstructed views and natural light transmission are desirable – such as curtain walls and skylights.

Probably the most common and widely seen application is structural glass facades, which give larger buildings a sleek and modern look while maintaining insulation and energy efficiency. Some buildings use structural glazing for the atrium only, creating a visually impressive light-flooded feature.

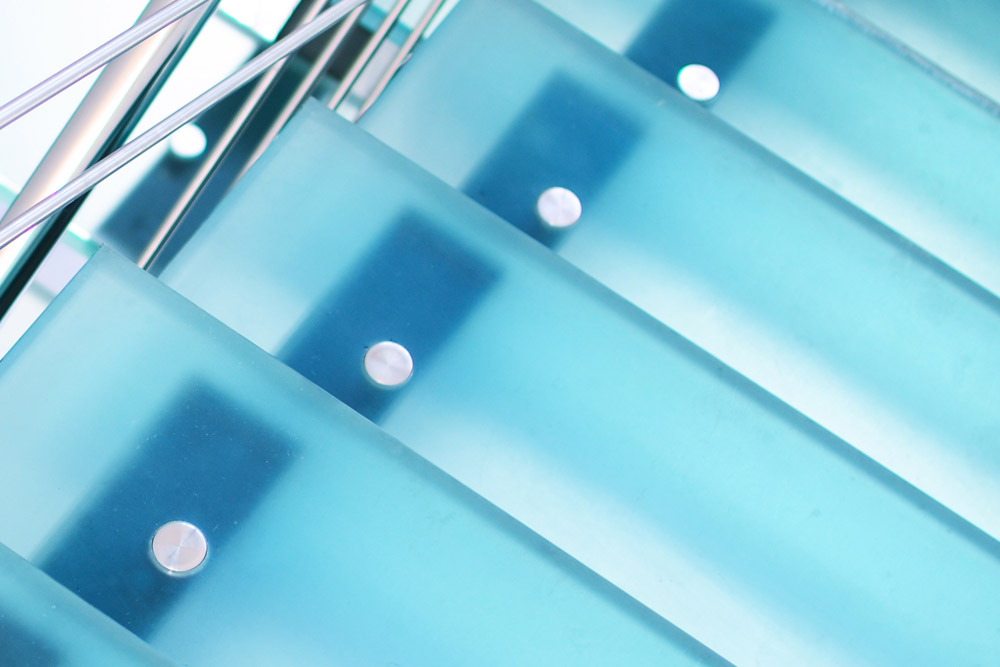

Aside from windows and walls, structural glass can also be used for staircases – either replacing traditional balusters and handrails, or using walk-on glass for the steps – and for landings, mezzanines, and balconies that require safety barriers without disrupting the view below.

Bridges and walkways in commercial buildings also tend to use structural glazing to keep the space as open as possible while meeting performance requirements. The glass can be used for the floor, barriers, or canopies above to provide some shelter without blocking the light from above.

These are just some of the many possible ways that versatile structural glazing can be applied in various building designs and property styles.

What are the benefits of structural glazing?

There are countless benefits of using structural glass over other building materials, like wood, concrete, and metal, in certain applications. The most obvious is that structural glazing is simply far more aesthetically appealing, especially for multi-storey buildings wanting to display a contemporary look that attracts more people.

The second most popular reason for choosing structural glazing is that it reduces dependence on artificial lights, instead allowing sunlight to spread through spaces that would otherwise be darker and closed off. This is important for our health, as exposure to natural light is necessary to regulate biorhythms and improve productivity.

The toughened or laminated glass specially manufactured for structural use is also extremely robust, ensuring you’ll get great value from your long-lasting investment. It’s highly resistant to scratches, corrosion, and temperature changes, as well as being strong enough to ensure safety and security.

Cost-effective, sustainable, and versatile – structural glazing can help to reduce sound transmission and heat loss, all while looking spectacular and giving your building a distinct architectural style. Clever use of structural glass can make properties more attractive and energy efficient, thereby increasing their value, too.

Why use structural glazing?

One of the biggest advantages of structural glazing is that the lack of framing systems gives architects and designers more opportunities to create truly stunning installations of glass for their buildings. This allows a much wider scope and greater flexibility in creating a completely bespoke design.

The only factors restricting the maximum size of structural glass panels are your budget and site access limitations. The thickness of the glass will help to increase the building’s energy efficiency, with thermal technology maintaining an ambient temperature instead of trapping too much heat.

Large expanses of glass are eye-catching from the outside and offer unrivalled open views of the surrounding area from the inside. Not only does it physically increase usable interior and exterior space, but it also tricks the eye into thinking it’s even more spacious due to the flood of light.

What are U values and loading values in structural glazing systems?

There’s a lot of in-depth engineering involved in a successful structural glazing installation. The physical performance of each glass panel is far more important than how it looks, which is why so many calculations go into ensuring that your bespoke glazing is structurally sound.

Factors that require extensive consideration when selecting structural glass qualities include:

- Thermal insulation

Structural glass is given a ‘Ug’ value according to the amount of thermal energy that can pass through the centre of the pane itself. The lower the value, the better the insulation; you should never go for glass with a Ug value of more than 1.2 W/m2K for structural glazing.

Th ‘Uf’ value refers to the thermal performance of the framework, while ‘PSIG’ indicates the performance of glazing spacers. These can all be combined into an overall ‘Uw’ value, sometimes referred to as simply the U value, using test methods standardised by BS EN 673:1998.

- Acoustic reduction & fire rating

You may be familiar with seeing sonic insulation ratings in decibels, but acoustic reduction values are represented by an ‘Rw’ figure for structural glass. Decibels measure acoustic power, and hertz measure vibration frequency; both go into the calculations for Rw standardised by EN ISO 717-1.

As for fire-rated glass, it needs to be fire-tested at its full size as per the intended installation before it can be used for structural purposes. Any fixings will also need to be fire-rated. You can find out more about how fire ratings for glass work on our Fire Rated Glass Partitions & Doors page.

- Line load & maintenance load

Since the glass is expected to bear a heavy structural load, your design must be tested to ensure that it meets all the necessary load-bearing requirements. You cannot legally install structural glass that is not fit for purpose due to the obvious safety risks, which is why prior testing is mandatory.

Vertical glass panels must be able to withstand a particular line load – such as the weight of a person leaning on a glass barrier. The glass specifications and fixings must bear the appropriate load for its intended purpose. The same applies to horizontally installed panels, which must be able to bear an adequate maintenance load – like the weight of a person accessing a roof for repairs.

Exterior walls and facades will also need to withstand a wind load of no less than 0.5kN to ensure that the structural glass won’t crack, bow, or break under the pressure of strong winds. Buildings by the coast or at high altitudes are likely to have much higher wind load requirements.